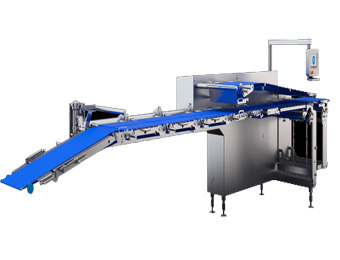

Germany Weber weLOAD

The automatic infeeder weLOAD is an especially compact infeeder that takes the portions created by an upstream unit and places them in a die format suitable for the downstream thermoforming packaging machine. Reloading times of the slicer can be compensated by the integrated buffer area, ensuring a continuous and effective running of the packaging line (depending on the configuration of the buffer area). The automatic feeding of the packaging machine takes place with a transfer that is synchronized with the foil chain.

The scalable weLOAD model range offers solutions from infeeders for standard applications to high-end specialists and can therefore be flexibly adapted to your individual needs. In addition to an extremely compact footprint that allows better accessibility to all areas, the weLOAD infeeders impress with an optimized portion flow and smooth portion transport. The special “GentleTransport” software makes it the perfect solution for sensitive products and applications and generally facilitates full automation without requiring subsequent manual correction or monitoring.

Due to the interaction between an intelligent controller and the comprehensive network of line components, which facilitates direct communication between line components such as cheese block divider, scanner, infeeder, and slicer, empty packages can be reduced to a minimum. Ultimate effectiveness of the empty package reduction option is achieved with cheese applications in connection with the weDIVIDE cheese block divider because the carriage is controlled via digital integration as well and the weights of the individual cheese blocks are spread evenly prior to the start of the process. This batch optimization is a clear advantage in terms of sustainability and profitability.

Application:

cheese, raw sausage, smoked pork chop, boiled sausage, cooked ham, aspic, bacon, pork tender loin, smoked ham, serrano ham, etc.

Advantages:

Smooth portion transport over all conveyor units of the infeeder (gentle transport)

Optimized portion flow

Precise infeeding accuracy

Optional sorting conveyor for rejecting missing portions

Compact and uniform design of all machine stands (less space required and better accessibility)

Complete software integration in Weber-

Empty package reduction (optional)

Twist correction (optional)

Automatic track position correction (optional)

Product Details:

High-performance infeeder for 2 on 2 applications of unstable portions

Special machine housing allows horizontal portion transport