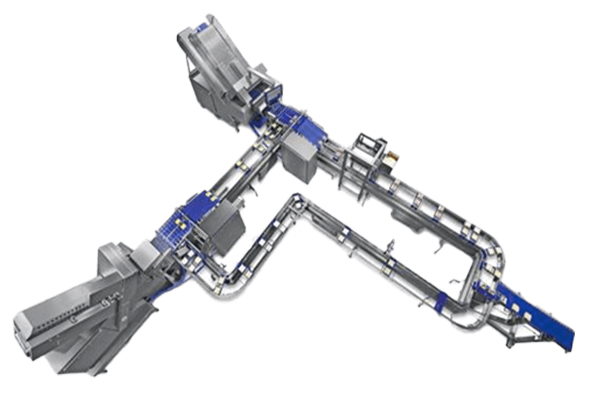

Germany Weber weSHUTTLE

The Weber ShuttleSystem (WSS) sets new standards in food production and offers a flexible alternative to the conventional transport of portions via belt systems. E.g. sausage, ham and cheese portions are conveyed by the Weber ShuttleSystem in single units, precisely and gently to one or more handover points. Whenever needed, single portions can be accessed anytime during their transport.

Applications:

cheese, raw sausage, smoked pork chop, boiled sausage, cooked ham, aspic, bacon, pork tender loin, smoked ham, serrano ham, etc.

Advantages:

Gentle transport of single portions

All slicers as well as all other machines connected up- and downstream are decoupled through an integrated buffering functionality, ensuring continuous production

WSS is flexibly expandable: from simple entry solutions to high-end lines for complex infrastructures (as a stand-alone solution or coupled with existing Weber slicers)

High dynamic and portion transfer performance guarantee maximal throughput

Barrier-free transport

Product Details:

Tailor-made

Easily adaptable to constructional circumstances

Small footprint

Specialization

Flexible line concepts, expandable through components

Creation of variety packs