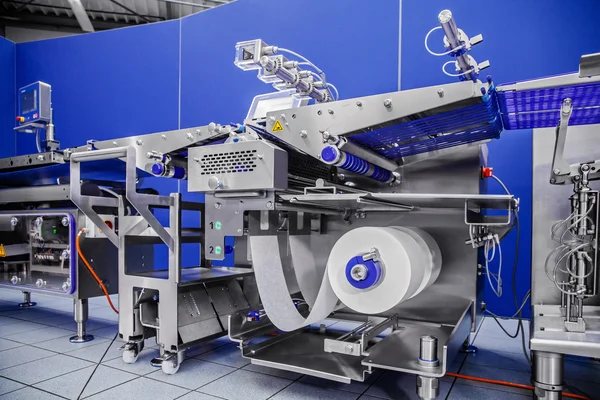

Germany Weber weUNDERLEAVE

Description:

More power, more sustainability, better hygiene: that is the new Weber weUNDERLEAVE. The underleaver automatically places paper or foil under all types of sausage, cheese or vegetable cold cuts and portion forms. In doing so, it operates in two lanes independently as the paper or foil can be fed and cut on two lanes fully independently from each other. Different foil types in various sizes can be processed using the weUNDERLEAVE. This ensures an individual adaption to the product and application. The Weber underleaver is perfectly suited for use in the sectors of food service, layout bacon, carpaccio and bakery products.

Light barriers for position detection on the infeed side ensure for the precise positioning of the underlays. Thanks to the lane position correction on the side that can be carried out manually via the Weber Power Control or fully automated, the portions are carried out aligned precisely. The Weber underleaver is suitable for use on maximum four lanes. The assembly and disassembly of all parts carrying products can be carried out conveniently without using tools.

Application:

cheese, raw sausage, smoked pork chop, boiled sausage, cooked ham, aspic, bacon, pork tender loin, smoked ham, serrano ham, etc.

Advantages:

Individual accuracy and more sustainability thanks to real two line capability

Good accessibility for changing rollers

Cassette-type slicing system

Also available as stand-alone variant

IIoT-ready

Product Details:

Independent processing on 2 lanes

Fully automatic lane position correction

Open hygienic design

For high performance ranges