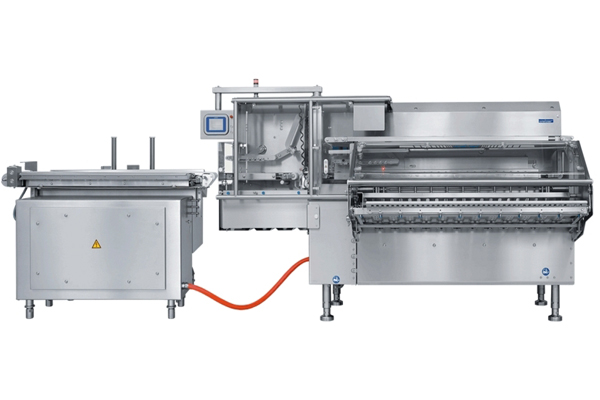

Germany Weber Peeling machine CCP

Description:

The Log Peeler CCP fully automatically and hygienically removes the casing from sausage and cheese products. The machine can be put together individually. A clear distinction between gray zones and hygiene zones allows the product casing to remain in the gray area, which increases the safety of the peeled product. With continuous production, the buffer can be inserted both upstream and downstream of peeling. The flexible system permits simple and rapid conversion when changing calibers.

Application:

cheese, raw sausage, smoked pork chop, boiled sausage, cooked ham, aspic, bacon, pork tender loin, smoked ham, serrano ham, etc.

Advantages:

Safety and product flow: control of the peeling removal and possible buffer after peeling

Individual compilation possible

Reduced personnel costs

Flexible: simple and rapid conversion when changing calibers

Optional hygiene kit:

UVC irradiation from underneath of conveyors in the product contact area

UVC air disinfection within the peeling area

Product Details:

Removes the casing from sausage and cheese products fully automatic and hygienically

Continuous production: the products are loaded automatically and buffered before the peeling process

Food safety: the product and casing are strictly separated